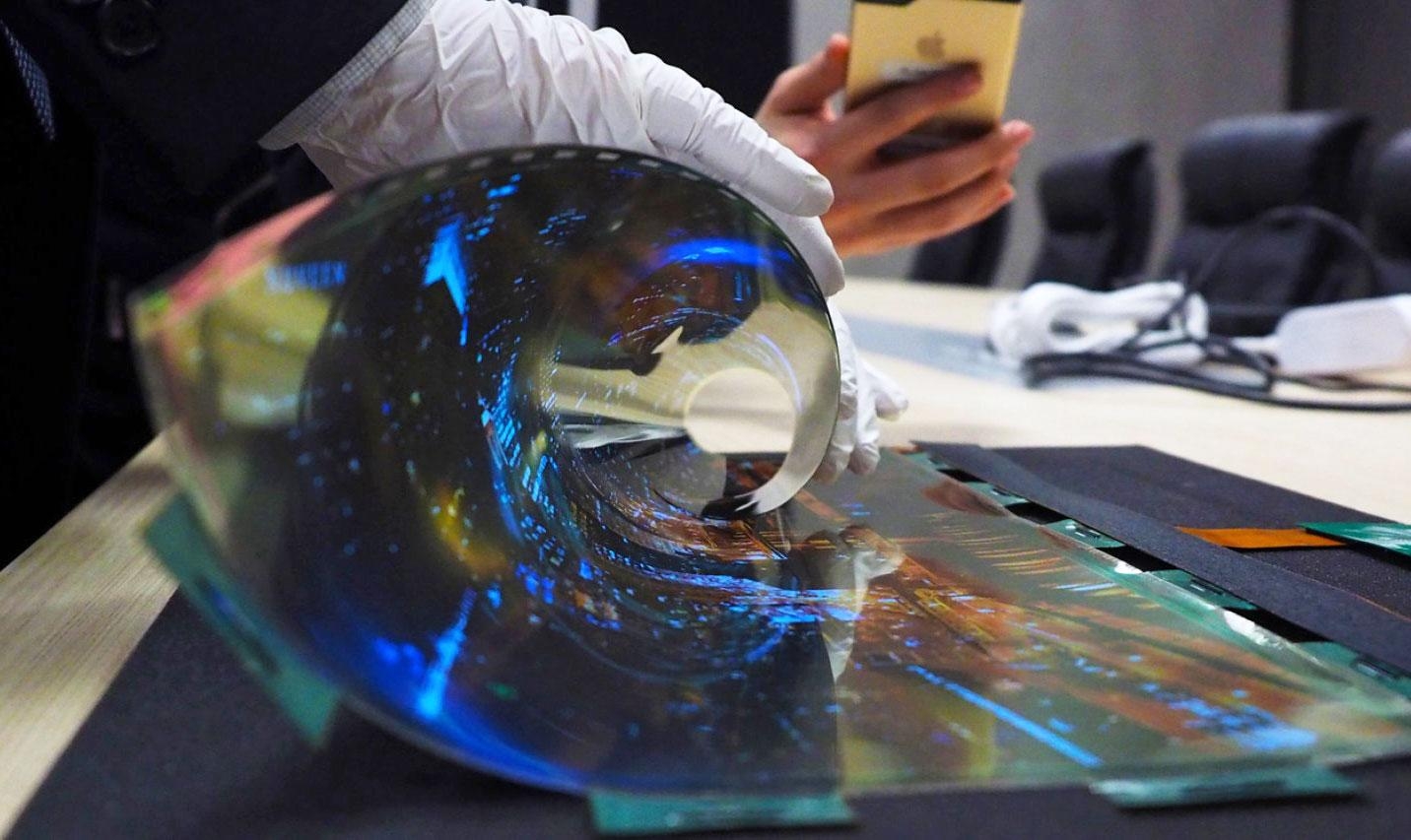

Flexible LED screens are a modern screen technology concept that is popular nowadays. It is a departure from the traditional LED screen structure due to substrates’ addition on either side and a rubber coating on the outer side. These factors offer screen flexibility.

Over the years, there has been a steady rate of development in flexible LEDs. It began to imitate paper properties and showcase digital images. The underlying need is to try to replace traditional papers on a commercial scale. Development dragged on for a while, only to pick up in the last decade. Below are some of the technical details for flexible displays.

FOLED (Flexible Organic LED)

OLED is a sub-category of flexible screens that utilizes plastic substrates and electroluminescent organic semiconductors. The manufacturer lays the semiconductors on the substrate to allow for usability when bent or twisted. The materials and layers are often nanometer-thin and use PET (polyethylene terephthalate).

Due to their flexible nature, FOLEDs are prone to residual deformations and thermal stress. Thermal stress can exist from the external applied pressure and changes in the operational temperature. It can affect features such as maximum brightness and overall efficiency.

Also, flexible displays are susceptible to reactions of moisture and air. The elements would cause encapsulation, which degrades the panels over time. One of the workarounds to the issue is coating the LED screen with glass to reduce or outrightly eliminate contact between the board and the elements.

Benefits of flexible LED screens

Flexible LED screens have a variety of uses, from foldable displays to cylindrical structures. Some of the benefits of rollable LED in the present application and prospects include:

- Flexible LED Screens save Space

Traditional LEDs have a rigid shape, which means they have to fit into discrete form factors. It invariably increases their thickness, thereby taking more space. On the other hand, an indoor flexible LED display already live in rubber cases and can maintain a light footprint all around. Such space savings open up opportunities in screen technology development, as recently seen in modern smartphones.

- They are Lightweight

Standard LED cases can include protective layers and other additions (like digitizers and touch-sensitive layers), and the overall weight and size increases exponentially. Flexible LEDs generally don’t need add-ons and have a light base to work. It is an extension of their space-saving flexibility.

- Extensive Modular Options

Flexible LEDs can seamlessly attach using straightforward magnetic buckles. It allows panel replacements quickly and opens a host of installation ideas and methods. The LED panels appear “stitched” with a discreet design.

Conclusion

There are many commercial use cases for flexible displays, and the prospects have improved over the last few years. It is more common to find flexible OLEDs in public places such as sports centers, malls, train stations, etc.

The low cost of acquisition and servicing helps scaling the development of an indoor flexible LED display for other commercial uses. You can consider the technical qualities and benefits mentioned above for flexible LED manufacturing and shipping operations.